OEM

small quantity and many varieties

high quality high precision

Short delivery period

Make samples

Reliability Testing

processing with supplied materials

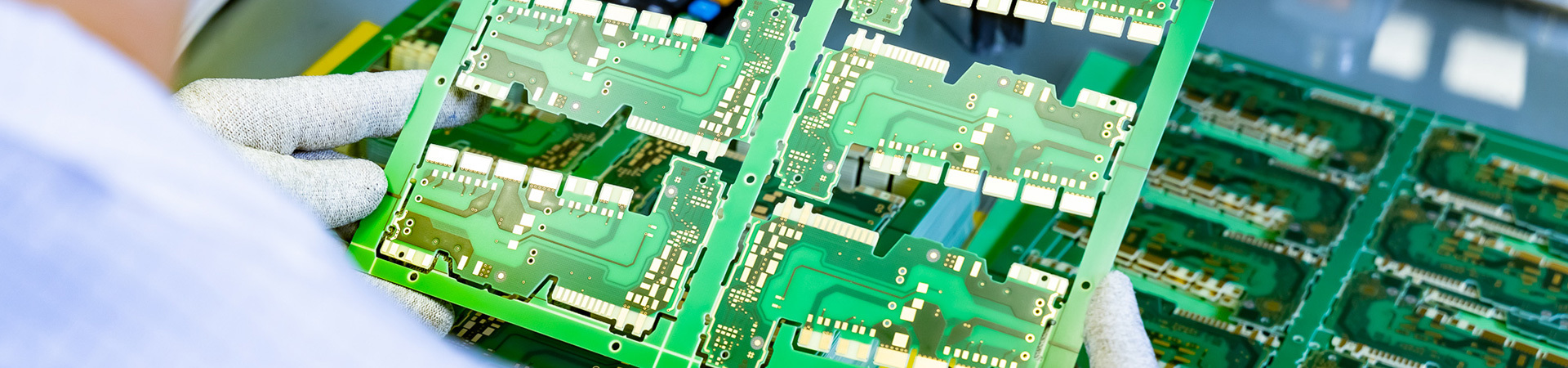

Equipped with two full-automatic high-speed SMT patch production lines, full-automatic board loading machine, full-automatic solder paste printing machine, SPI solder paste thickness detector, multi-temperature zone reflow soldering, AOI optical detection equipment, X-Ray ray inspection machine, steel mesh cleaning machine, laser engraving machine, etc. The company has passed the certification of ISO9001 quality management system and ISO14001 environmental management system, supporting the mounting of 0201 components, 0.4mm Pitch BGA, QFN and other precision electronic components. Can undertake a small number of varieties, high quality the requirements of high precision OEM needs.

OEM

Part purchasing:The company has long-term cooperation and stable procurement channels, can achieve small batch to large batch procurement of products, more favorable prices, better delivery.

Precision Machining:According to customer specifications processing → quality control → inspection → shipment. Meet the production needs of small batch and many varieties to large quantities.

Short delivery time: BOM, Geber,Coordinate data and other data are available, including parts procurement, samples can be delivered within one week at the earliest.

POS Terminal Display Module

Smart Home Wall Switch PCBA

Smart Watch PCBA

Remote control PCBA4

Equipment Capability

| Capacityitem | Metricmm | Inch" |

| MinimumICPitch | 0.3mm | 0.012" |

| MinimumChipsize |

0201* |

8004 |

| MinimumChipsize Actua1production |

0603* |

201 |

| PCB Substratesize |

50mmx50mm~ |

1.97"x1.97"~ |

| PCB thick | 0.3mm | 0.012" |

| The best implementation size | 20 | 0.787 |

| Number of implementations/Hr | 157,400 point | |

| Placement Accuracy | ±0.025mm |